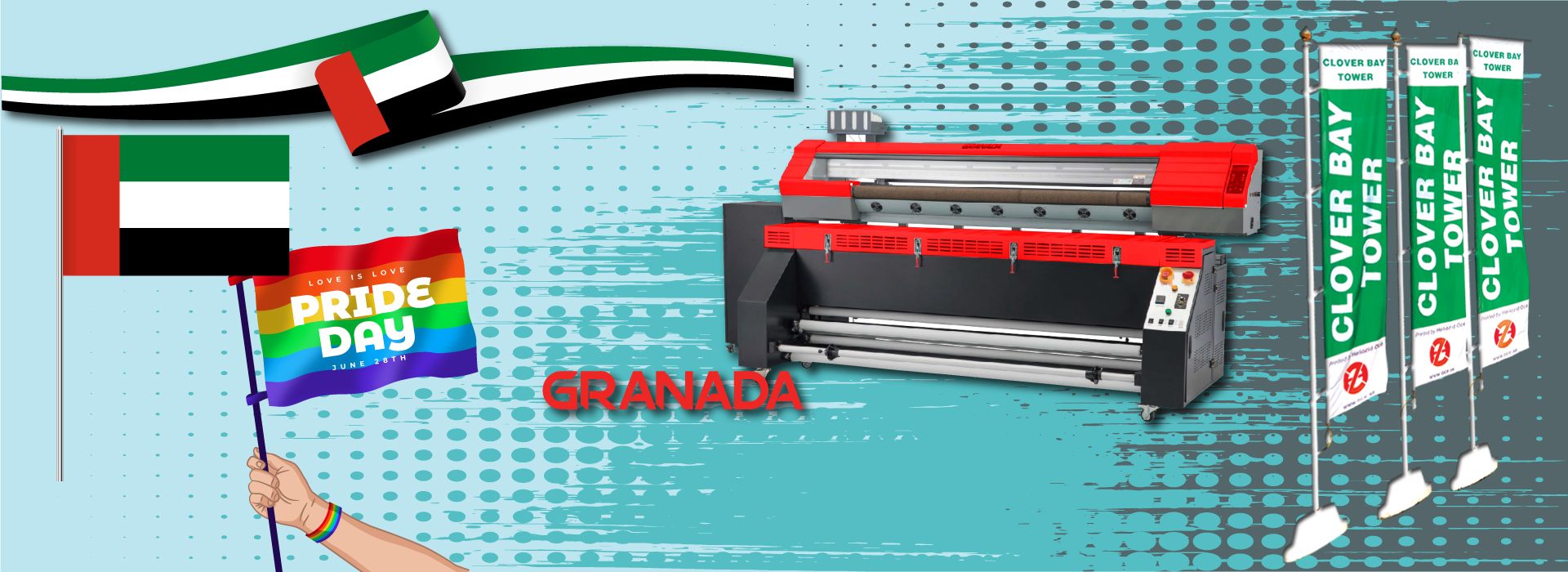

Granada 1800 TX

Woven Fabric Digital Printer

Digital printing for Flags, AD & SIGN and Outdoor Textile Banner

Features

- Constant traction stepping system helps the fabric in the floating state with good flatness when being printed. The traction is adjustable, which substantially broadens the fabric adaptability.

- Fabric will enter into the drying process right after printing to avoid the sticky dirt generated on the fabric while entering into a twitch roller. The drying temperature and wind force is adjustable to ensure the adaptability of a fabric which is thin or thick.

- Excessive ink droplets passing through the fabric during printing would be uniformly collected by the waste ink tank and required to clean the waste ink tank regularly to avoid drainage of waste water. The system can easily handle ultra-thin fabrics

- Two-sided-heating and fully-closed design can meet the requirements of sublimation with full color development. It is also used as the drying unit. The energy efficiency can be improved and the electricity consumption can be reduced.

- Professional RIP Software supports the hyperfine screening technology conducting multi-channel color separation with a unique function of multiple duplicating. It can fully respond to the

requirements of various patterns by the digital printing.

Specifications

| Printhead | 5th Generation Micro Piezo Electric Printhead(DX5) 180 Nozzles x 8 rows x 2 CMYK 4 Color (2880 Nozzles) 1440dpi |

| Print Technology | 360X1080dpi @55sqm/hr 720X720dpi @33sqm/hr 720X1080dpi @26sqm/hr Maximum Print Width = 1800mm Maximum Material Width = 1880mm Material Type = Polyester |

| Heating system | Sublimation Heater |

| RIP Software | PHOTOPRINT Textile Version, ONYX Textile Version |

| Control Software | Printer Manager |

| Ink | Disperse Dye Sublimation Ink |

| Ink-Supply Mode | Continuous Ink Supply System(ClSS) |